Reference producer in the pulp and paper sector

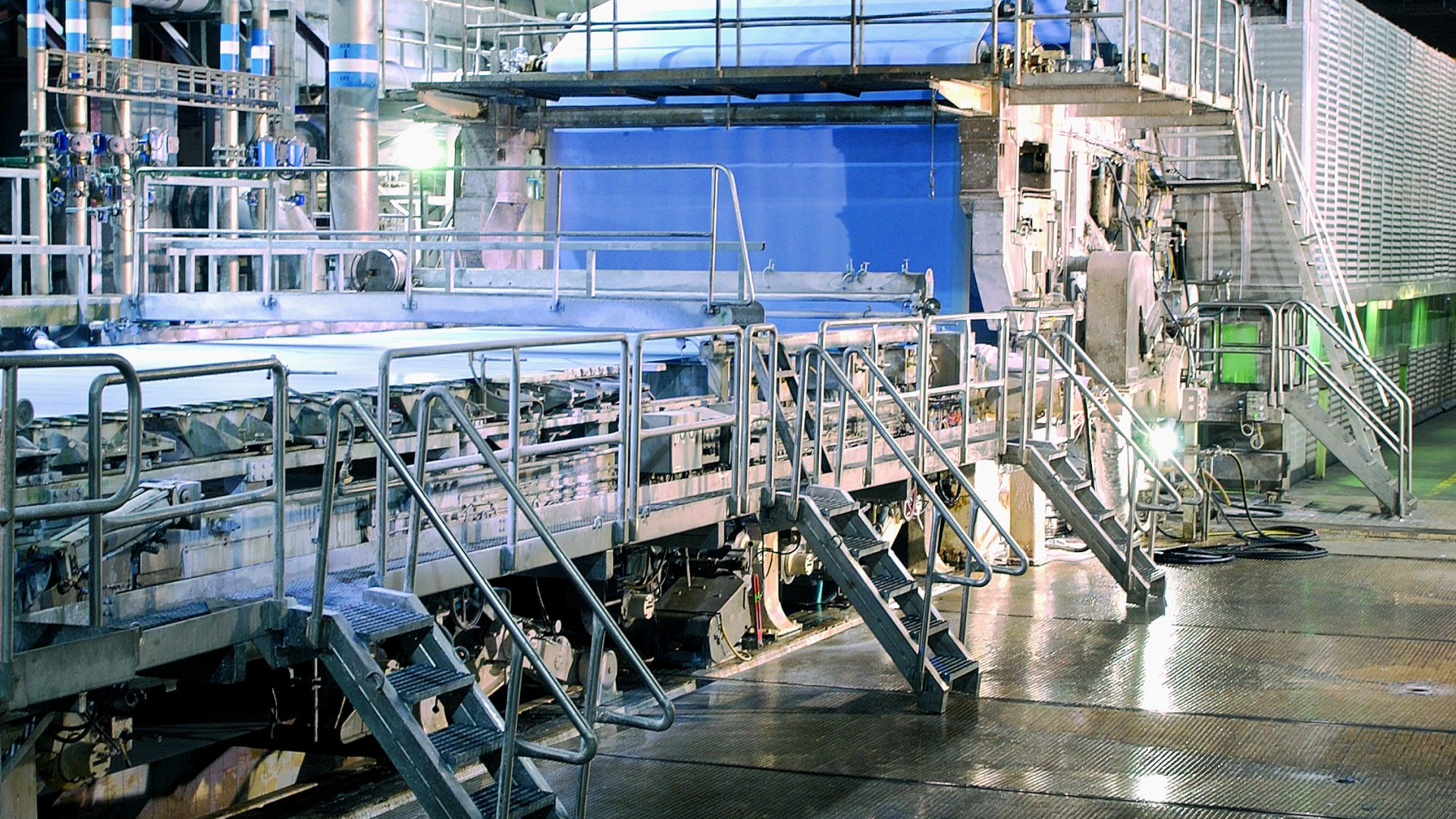

Recently, Navigator approved the final investment decision of €30 million for the conversion of its PM3 machine (Paper Machine No. 3), located in the integrated industrial complex of Pulp, Paper and Packaging in Setúbal. With this project, it reinforces its position in the European flexible packaging papers market (kraft papers), establishing itself as one of the reference producers in the sector.

The new operation is scheduled to start in the third quarter of 2026, with an annual production capacity of 100,000 tonnes, maintaining operational flexibility for printing and writing paper production.

The conversion will enable the production of papers in a grammage range between 30 and 90 grams per square meter, responding to the growing demand for sustainable solutions in various food and non-food segments, following the migration trend towards natural, renewable and biodegradable-based solutions.